Product navigation

-

Hexagon bolt

View More

Hexagon boltView More

-

Steel structure bolt

View More

Steel structure boltView More

-

Hexagon nut

View More

Hexagon nutView More

-

Galvanized bolt

View More

Galvanized boltView More

-

Cement bolt

View More

Cement boltView More

-

Chemical anchor bolt

View More

Chemical anchor boltView More

-

Mechanical anchor bolt

View More

Mechanical anchor boltView More

-

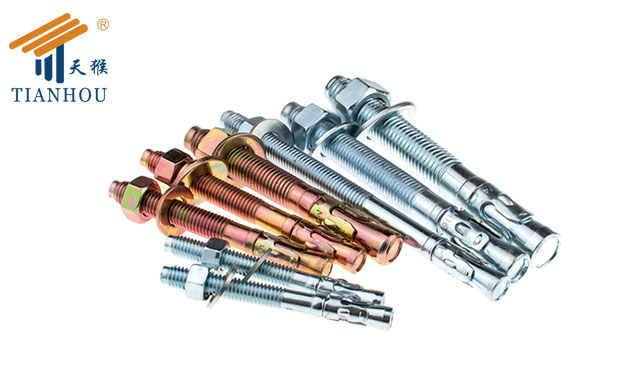

Expansion bolt

View More

Expansion boltView More

-

Wedge Anchors

View More

Wedge AnchorsView More

-

Casing gecko

View More

Casing geckoView More

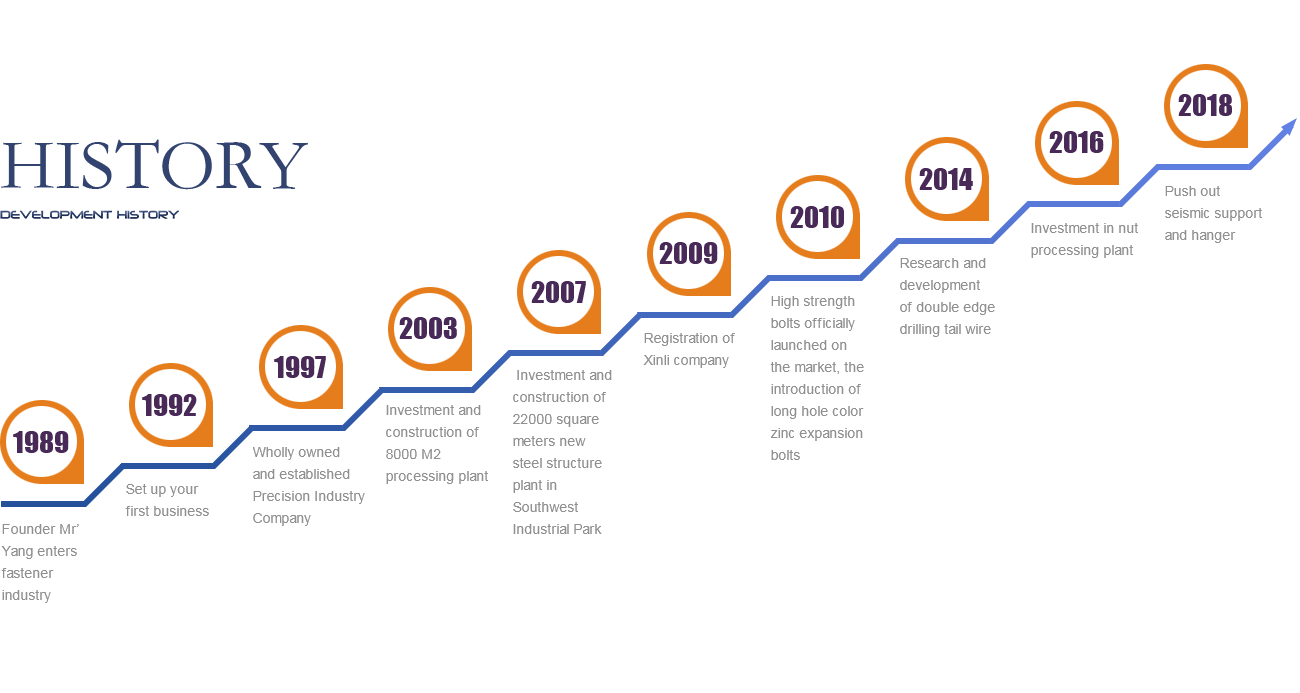

Hebei Xinli Fastener Co.,Ltd.

Hebei Xinli Fastener Co.,Ltd. Is specially engaged in the production and research of high quality fastener, with all kind of high strength fastener and also the company process the refinedsteel wire production. The factory zone covers an area of over 50000 square meters, and it annually produces more than 40000 tons of fasteners and near 50000 tons of refinement steel wire every year. Our product fully completely conform with the customers requirements.

-

20Year

Twenty years of production experience

-

300+

Existing staff

-

300+

Quality project

-

5Tons

Annual production capacity of 50000 tons

-

3Million

The annual output value is 300 million yuan

Enterprise strength

Hebei XINLI provides

-

Material quality control

Raw material quality is the basis of product quality. Each batch of raw materials is tested according to the batch heat number. The company has established a scientific supplier management system, with high quality standards for assessment, to ensure the high quality level of raw materials.

-

Product inspection

Every link of product production is tested by full-time inspectors. And supporting all aspects of the laboratory, to ensure that each link has adopted a "zero defect" management plan, unqualified products can not enter the next process. From the cold heading workshop, heat treatment workshop, packaging workshop to retain complete test data, timing statistics and analysis.

-

Transportation guarantee

The company sets up logistics channels all over the country to ensure that the goods will be delivered to the designated place within the agreed time.

-

after-sale service

Telephone support: through telephone or fax, professional and technical personnel will be arranged to understand the specific situation of the product within the specified time, and come up with solutions to finally eliminate the problem. On site support: for problems that cannot be solved by telephone, technical personnel will be arranged to go to the site to analyze the causes, formulate plans and solve problems.

-

原材料控制

原材料质量是产品质量的基础。每一批原材料进厂,都按照批次炉号进行测试。公司建立科学的供方管理体系,以高要求的质量标准进行考核,确保原材料的高质量水平。

-

产品检验

产品生产的每一道环节,都有专职的检验人员进行测试。并配套全方面的实验室,确保每一道环节均采取了“零缺陷”的管理方案,不合格品不能进入下一道工序。从冷镦车间、热处理车间、包装车间保留完整的检测数据,定时统计和分析。针对异常情况,迅速响应,由专业的质检人员组织开展纠正预防。

-

物流运输保障措施和供货期限

公司配套全国各地的物流渠道,保证在约定时间内将货物送到指定地点。

-

售后服务保障措施

电话支持:通过电话或传真形式,将安排专业技术人员在规定时间内对产品具体情况了解,并拿出解决方案,最终排除问题。 现场支持:通过电话不能解决的问题,将安排技术人员赴现场分析原因,制定方案,解决问题。

HEBEI XINLI FASTENER CO.,LTD.

- TEL:

- 0310-5607558

- MAIL:xinli@hbxljgj.com

- Address:South west industrial area ,Yongnian county ,Handan city ,Hebei province ,China

XinLi Fastener

XinLi Fastener

WEIXIN CODE

冀ICP备8008074587-2号